Frist Industrial pipeline inspection camera systems are becoming increasingly valuable in various industries, including the wind power sector. Here’s how these CCTV pipe inspection systems can be applied effectively within the wind power industry:

1. Inspection of Hydraulic Systems

Wind turbines utilize hydraulic systems for various functions, including blade pitch control and braking systems. Industrial Pipeline inspection camera can be used to:

- Inspect Hydraulic Lines: Regularly check for leaks, blockages, or wear in hydraulic lines.

- Ensure Cleanliness: Verify that hydraulic lines are free from debris and contamination.

- Diagnose Issues: Identify problems such as corrosion or damage that might affect hydraulic performance.

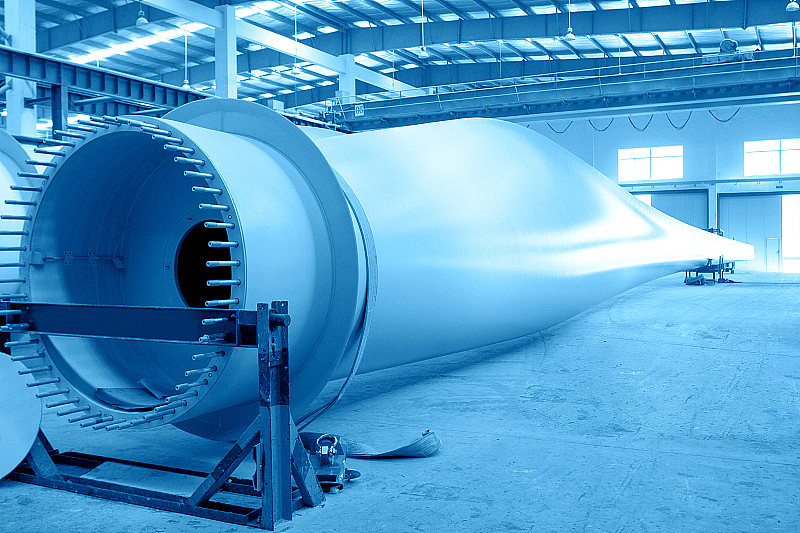

2.Wind turbine blade inspection

Pipe inspection robot camera system can inspect Wind turbine blade defects such as sand holes, cracks, drain pipe blockage, and surface shedding.

- Climbing Robots: Some advanced robots are designed to climb and traverse the blade surface, equipped with cameras and sensors to perform inspections while the turbine is operational or stationary.

- CCTV Crawler Robots: These robots move along the blade surface and can be equipped with various sensors and imaging technologies for thorough inspections.

3. Maintenance of Cooling Systems

Wind turbines, particularly large ones, use cooling systems to manage temperatures in their generators and other critical components. Industrial Plumbing Inspection cameras can help by:

- Monitoring Cooling Pipelines: Inspecting cooling lines for signs of wear, leaks, or blockages.

- Assessing Thermal Management: Ensuring that cooling systems are functioning optimally to prevent overheating and potential damage.

4. Inspection of Cable Conduits

Wind turbines have numerous electrical cables running through conduits. Pipeline cameras can be used to:

- Check Conduit Integrity: Inspect conduits for damage or obstructions that could affect the electrical system.

- Prevent Electrical Failures: Identify issues before they lead to electrical failures or system outages.

5. Monitoring and Inspecting Lubrication Systems

Wind turbines require lubrication for various moving parts. Tube Inspection cameras can assist by:

- Checking Lubrication Lines: Ensuring that lubrication lines are clear and functioning properly.

- Identifying Leaks: Detecting leaks in lubrication systems that could lead to inadequate lubrication and component wear.

6. Assessing Tower and Nacelle Components

While not directly a pipeline application, Pipe video inspection cameras can be used in tower and nacelle components that may include internal piping or tubing:

- Internal Inspections: Inspecting internal components of the nacelle or tower for signs of wear or damage.

- Safety Checks: Ensuring that all internal systems are functioning as intended and identifying any potential safety issues.

7. Facilitating Remote Inspections

Given the remote locations of wind turbines, using pipeline inspection cameras enables:

- Remote Monitoring: Conducting inspections from a distance, which can be particularly useful for offshore or hard-to-reach turbines.

- Reducing Downtime: Performing inspections without the need for extensive disassembly or manual inspections, reducing downtime and maintenance costs.

8.Enhancing Predictive Maintenance

By integrating pipeline inspection cameras with predictive maintenance systems, operators can:

- Gather Data: Collect detailed visual data on the condition of pipelines and associated systems.

- Analyze Trends: Use data to predict potential failures and schedule maintenance before issues become critical.

9. Supporting Safety and Compliance

- Regulatory Compliance: Ensuring that inspection and maintenance activities meet industry standards and regulatory requirements.

- Safety Inspections: Identifying potential safety hazards in pipelines and associated systems to prevent accidents and ensure safe operations.

In a word, industrial pipeline inspection camera systems enhance the efficiency, safety, and reliability of wind turbines by providing detailed, real-time insights into critical systems. This proactive approach helps to maintain the performance and longevity of wind power infrastructure.