Offshore oil platforms are fixed or floating structures. It used for oil and gas exploration, production and processing in the ocean. They are usually built far from the coastline to exploit oil and gas resources on the seabed. Offshore platforms are designed and built to cope with extreme conditions in the marine environment, such as storms, waves, corrosion, and changes in seabed geology.

Offshore oil platforms and ships are in a harsh marine environment and face multiple risks such as extreme weather, salt spray corrosion, mechanical wear, and structural aging for a long time. Therefore, regular and accurate non-destructive testing (NDT) of their structures is crucial. These detection methods help ensure the safe operation of platforms and ships, prevent catastrophic failures, ensure the safety of personnel, and reduce maintenance costs.

First: The importance of NDT inspection camera in Offshore Oil Platforms and Ships

- Corrosion and wear monitoring: Saltwater and humid air can cause corrosion and degradation of metal structures (such as steel). So regular non-destructive testing helps identify potential corrosion, cracks or other damage.

- Structural integrity assessment: Structural safety is critical in the design and operation of offshore platforms and ships. Non-destructive testing can accurately assess the strength of supporting structures, pipelines and shells to ensure their load-bearing capacity and durability.

- Reduce downtime: By identifying potential defects in advance, non-destructive testing can avoid emergency repairs and downtime, thereby reducing the impact on production or transportation.

Second:Commonly used non-destructive inspection methods

Commonly used NDT methods for offshore oil platforms and ships include cctv crawler camera inspection, pipe push rod camera inspection、videoscope camera inspect、ultrasonic testing, radiographic testing, magnetic particle testing, penetration testing and other NDT inspection camera etc. Each method has its own unique advantages and is suitable for different testing needs.

1、CCTV pipe crawler camera

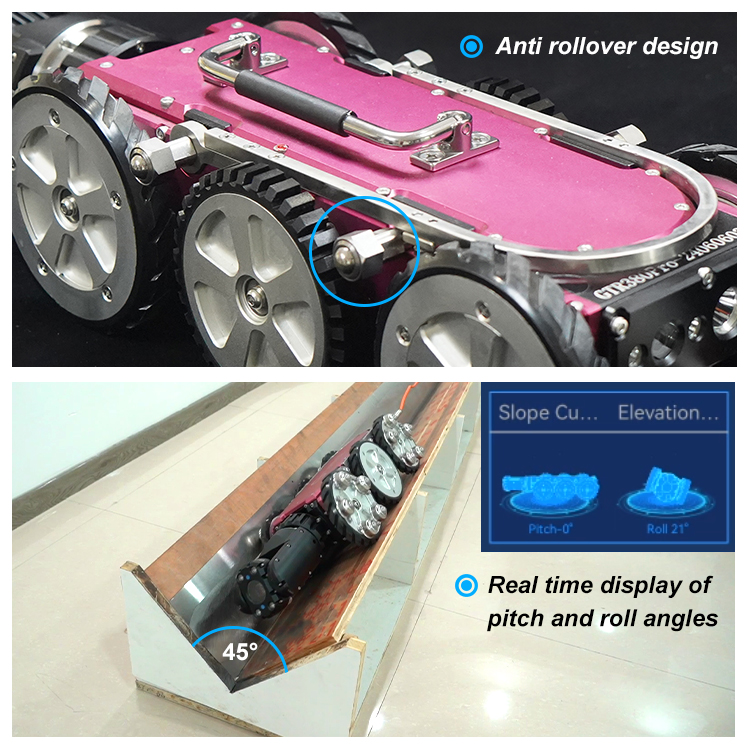

CCTV pipeline crawling camera is a high-tech device specially designed for monitoring underground pipeline networks. These inspection cameras are usually installed on small remote-controlled crawling robots, and provide clear visual data through internal video monitoring of pipelines to help detect problems such as blockages, cracks or corrosion.

Main features:

- HD imaging: Equipped with 4MGP cameras, it can capture clear and detailed images and videos for easy analysis of pipeline conditions.

- Strong flexibility: The miniaturized design is suitable for pipelines of various diameters and can move freely in narrow spaces.

- Real-time recording:Real-time transmission of video data, while supporting storage for subsequent analysis.

- Waterproof :Adopting waterproof materials, it can work for a long time in harsh environments.

- Remote control:Through wired or wireless remote control systems, operators can complete inspection tasks without entering dangerous areas.

Main applications:

- Municipal pipeline inspection

- Used to check the blockage and damage of urban underground water supply and drainage pipelines.

- Industrial pipeline maintenance

- Regular inspection of the inner wall of oil and gas pipelines to prevent leakage and explosion accidents.

- Pre-cleaning inspection of sewage pipelines

- Construction project inspection

- Quality inspection of newly built pipelines to ensure compliance with construction standards.

- Offshore oil platforms and ship plumbing inspection

2、inspection push rod camera

An inspection push rod camera, also known as a push camera, is a device for inspecting hard-to-reach or underground areas, particularly in plumbing and pipe systems. It consists of a small, high-resolution camera mounted on the end of a flexible push rod, which is typically made of a durable, lightweight material. The camera is pushed or "fed" into pipes, drains, sewer or ducts to visually inspect the interior without the need for invasive procedures like digging or dismantling structures.

Key Features of an Inspection Push Rod Camera:

- HD Camera: Provides clear images or videos of the interior of pipes, drains, or ducts, which can be crucial for identifying issues like blockages, cracks, corrosion, or leaks.

- Flexible Push Rod: The push rod is typically long enough to navigate through tight spaces and curves in plumbing systems.

- Durability: The camera and rod are often waterproof, shock-resistant, and designed for harsh environments.

- Real-Time Viewing: Most models allow the user to view live footage on a monitor or connected device.

- Recording : Some models include features for recording video or taking still images for documentation and analysis.

- Built-in Lighting: LED lights are often incorporated around the camera lens to provide clear visibility in dark or poorly lit spaces.

Applications:

- Plumbing Inspections: blockages, leaks, or damage within pipes and drains.

- Sewer Line Inspections: Locating faults in sewer lines, including root infiltration, cracks.

- HVAC Systems: Inspecting ducts and ventilation systems for blockages or damage.

- Construction & Maintenance: Inspecting underground or hidden structures for condition assessments.

- Offshore oil platforms and ship pluming inspection

3、videoscope camera

A videoscope camera is a type of endoscopic inspection camera combines the features of both a borescope and a video camera. It is provide visual inspection of hard-to-reach or confined spaces with real-time video streaming capabilities. Typically, a videoscope camera consists of a flexible or rigid probe with a high-resolution camera at the tip, along with a controller or screen for viewing live video.

Key Features of Videoscope Camera:

- HD Camera: The camera provides HD or ultra HD video, offering clear and sharp images of the inspected area. Many models support zooming and focus adjustments for better clarity.

- Flexible or Rigid Probe: The probe, which houses the camera, can be flexible or rigid depending on the application. Flexible probes are particularly useful for navigating around corners or obstacles.

- LED Lighting: The camera head typically includes built-in LED lights that illuminate dark or confined spaces.

- Display Screen: Videoscope cameras often come with an integrated display screen, or they may connect to an external monitor, tablet.

- Recording and Playback: Many models feature video and audio recording capabilities, allowing users to capture footage for documentation, reports, or future analysis.

- Waterproof and Durable: Videoscope cameras are often built to withstand harsh conditions, with waterproof, heat-resistant, and chemical-resistant designs for use in demanding environments.

Applications:

- Industrial and Mechanical Inspections: For inspect engines, turbines, pipes, HVAC systems, and other mechanical systems. It is particularly useful for detecting internal damage, wear, or blockages without disassembling the equipment.

- Plumbing and Drain Inspections: Ideal for inspecting pipes and drains to locate clogs, leaks, cracks, or other issues.

- Offshore oil platforms、Aerospace、Automotive、Ship Inspections: aircraft and vehicle maintenance to inspect hard-to-reach parts, such as engines, turbine blades, or transmission systems.

- Construction and Building Inspections: Can be used to inspect walls, ceilings, ducts, and other structural components for hidden damage, mold, pests, or other issues.

4、Ultrasonic Inspect

- Application : steel structures, welded joints, pipelines and other parts to detect cracks, corrosion or other internal defects.

- Advantages: High precision, can penetrate thick materials, can provide accurate defect location and depth information.

- Technological development: With the advancement of digitalization and automation technology, ultrasonic testing instruments are becoming more and more accurate, capable of real-time data collection and remote monitoring.

5、Radiographic Inspect

- Application: X-ray inspection is often inspect welded joints, pipelines, pressure vessels and other parts, such as pores, cracks and inclusions.

- Advantages: It can view the internal structure of the material, especially suitable for thick-walled parts of metal materials.

- Challenges: It requires strict safety management and professional operation, and has high requirements for the operating environment.

6、Magnetic Particle Inspect

- Application: Suitable for surface or near-surface cracks in steel structures, especially for the steel parts of ship hulls and platforms.

- Advantages: It can detect surface cracks and near-surface defects. It is easy and fast to operate, and is suitable for rapid on-site inspection.

- Limitations: ferromagnetic materials and cannot detect deep defects.

7、Penetrant Inspect

- Application: Mainly detect tiny cracks, holes and other defects on metal surfaces, especially welding points and structural joints.

- Advantages: It has a good detection effect on surface defects and is suitable for any non-porous material.

- Limitations: It requires good surface cleanliness and can only detect surface or near-surface defects.

8、Eddy Current Inspect

- Application: Eddy current inspect is suitable for checking cracks, corrosion and wear on the surface of conductive materials.

- Advantages: High sensitivity, accurate detection of material surfaces, and no need to contact the material surface.

- Limitations: Poor effect on thick materials and requires professional operating techniques.

Third:Selection of inspection method

In the inspection of offshore oil platforms and ships, it is critical to choose the right NDT inspect method. Usually, it is necessary to combine the advantages of different methods for comprehensive judgment. You can also find a professional inspection company to give solutions or provide inspect services

Fourth: Application of advanced technology

- CCTV Crawler Robot and NDT Inspection Camera: Due to the offshore environment, more and more offshore platforms and ships are beginning to use robots and camera for NDT Inspection. These equipments can be remotely operated efficiently, reduce manual risks, and complete tasks in difficult environments.

- Data analysis and inspection report: With the development of AI and big data technology, modern NDT equipment can automatically analyze inspection data, generate real-time reports, and predict faults. This not only improves the accuracy of inspection, but also optimizes the maintenance cycle.

Fifth: The Challenges and Future Development Of NDT Inspection Camera

- Harsh environmental factors: Offshore platforms and ships often face harsh environments. such as storms, high humidity, and seawater corrosion.

- Data processing and analysis: With the increase in the amount of data, how to quickly and accurately process and analyze data has become a challenge. The application of AI and machine learning in this field provides new solutions.

- Remote monitoring: In the future, remote monitoring technology will become the trend of NDT inspection of offshore platforms and ships, especially the use of robots, caneras, drones and other equipment for remote inspection, which will greatly improve the efficiency and safety of detection.

Sixth:Conclusion

NDT Inspection Camera is an important means. It ensure the safety of offshore oil platforms and ship structures and extend their service life. By selecting appropriate inspect methods, combining advanced technical, accidents can be effectively prevented, risks can be reduced, and equipment reliability can be improved. With the advancement of science and technology, NDT in the future will be more intelligent and automated, and better serve the safety management of offshore oil platforms and ships.