The Difference Between Municipal Pipeline QV (Periscope inspection camera)And CCTV Inspection Crawler

Here’s an overview of the differences between Municipal Pipeline Inspection Quick View Camera and CCTV Inspection Crawlers for underground pipeline inspection:

1. Purpose and Application

QV (Quick View):

Initial assessment or rapid overview of pipeline condition.

- Primary Use: Initial assessment or rapid overview of pipeline condition.

- Application: Quickly identifies major blockages, collapses, or other significant issues without requiring detailed analysis.

CCTV Inspection Crawler:

Detailed and thorough inspection of pipeline interiors.

- Primary Use: Detailed and thorough inspection of pipeline interiors.

- Application: Provides high-resolution imagery and video for in-depth evaluation of pipeline conditions, including minor defects, cracks, or leaks.

2. Technology and Equipment

QV (Quick View):

- Equipment: A pole-mounted camera or portable system with limited mobility.

- Features:

- Typically a fixed or tiltable camera.

- Minimal or no motorized movement within the pipeline.

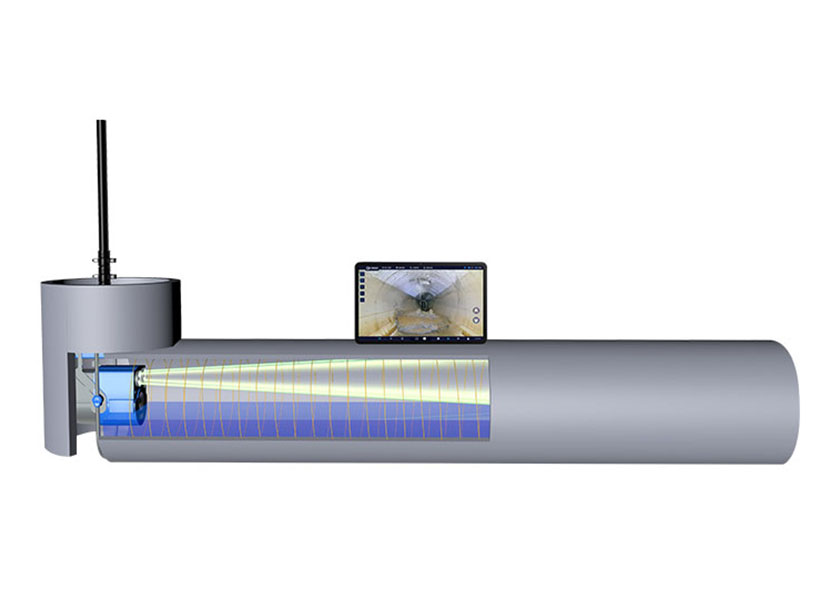

Pipeline QV periscope inspection

Pipeline QV periscope is a pipeline rapid inspection equipment.

It uses an adjustable length handle to put a high magnification camera

Into a manhole or hidden space

To inspect the Sewage drainage pipe.

QV periscope is mainly used for rapid inspection of the internal conditions of the pipeline

Applicable to pipelines with a diameter of 150mm-3000mm

Operators do not need to go down the well when using it

The detection length can reach 80 meters at a time

4 million high-definition pixels can clearly restore the internal details of the pipeline

You can also add a fill light device to identify damage~

CCTV Inspection Crawler:

- Equipment: A CCTV inspection robotic crawler equipped with a high-definition camera and crawler body controls.

- Features:

- Electrical cable reel winder,including movement along lengthy pipelines.

- PTZ camera capabilities for videos and photoes.

- Real-time inspection report system

Pipeline CCTV robot inspection

Pipeline inspection is the premise of repair and reasonable maintenance

The purpose is to understand the internal conditions of the pipeline

According to the internal conditions of the pipeline

It can be confirmed whether the pipeline needs to be repaired and what method should be used for repair

Scientifically formulate a maintenance plan.

3. Inspection Depth

QV (Quick View):

- Depth: Limited to visible areas within the pipeline.

- Range: Typically provides a surface-level or near-surface view of the pipeline.

CCTV Inspection Crawler:

- Depth: Can traverse the entire length of a pipeline segment, regardless of depth.

- Range: Covers long distances and provides a comprehensive internal assessment.

4. Time and Cost

QV (Quick View):

- Time: Faster set up and operation.

- Cost: Lower operational cost due to simpler equipment and quicker inspections.

CCTV Inspection Crawler:

- Time: More time-intensive due to set up, operation, and detailed analysis.

- Cost: Higher cost due to advanced technology and longer inspection durations.

5. Accuracy and Detail

QV (Quick View):

- Accuracy: Offers a basic understanding of pipeline conditions.

- Detail: Limited detail; not suitable for identifying fine cracks or minor defects.

CCTV Inspection Crawler:

- Accuracy: Highly accurate, capable of detecting and documenting fine defects.

- Detail: Provides detailed visual records for analysis and reporting.

6. Best Use Cases

QV (Quick View):

- Quick pre-inspection before a detailed analysis.

- Emergency checks to identify immediate issues.

- Situations with time or budget constraints.

CCTV Inspection Crawler:

- Comprehensive condition assessments.

- Planning pipeline repairs or maintenance.

- Compliance with regulatory or reporting requirements.

Conclusion

Municipal pipeline QV and CCTV inspection crawlers serve complementary purposes. QV is ideal for quick and preliminary assessments, while CCTV inspection crawlers provide the detailed information needed for in-depth analysis and decision-making. Choosing the right method depends on the inspection goals, budget, and the level of detail required.

✅The most commonly used detection tool at present is pipeline CCTV Inspection.

The CCTV system is installed on a self-propelled vehicle. It can enter the pipeline for video recording. The technicians interpret the pipeline condition based on the inspection video. The video can clearly find the defects inside the pipeline and accurately locate the defect points. Pipeline inspection is divided into two categories: structural condition inspection and functional condition inspection. 1⃣ Structural condition refers to the condition of the pipeline itself. This indicator is closely related to the structural strength and service life of the pipeline. 2⃣ Functional condition refers to the condition that occurs during pipeline operation. It is related to the water flow capacity of the pipeline. ⭕️ It can usually be improved through pipeline maintenance and dredging. It has little effect on the life of the pipeline.